+86 0755 2301 1202

info@mightyling.com

Building 1, Zhongzhan Technology Park, No. 9 Furong Road, Tantou Community, Songgang Street, Shenzhen

In today's era of widespread use of LED displays, point-by-point calibration has become a key technology for enhancing display quality. This technology ensures the overall uniformity and color accuracy of the screen by individually adjusting the brightness and chromaticity of each LED bead. So, why is point-by-point calibration necessary for LED displays?

1. Inherent defects of LED individual differences

The production process of LED chips determines the natural differences in brightness and color among individual beads. Even for products from the same batch, the brightness deviation may reach 10%-20%, and the chromaticity coordinate difference may even exceed 0.01. This variability can lead to issues such as color blocks and brightness spots on the screen, seriously affecting visual effects. For example, red LEDs typically have lower brightness, while green and blue LEDs have higher brightness. If not corrected, this can lead to color imbalance. The industry standard requires brightness uniformity of ≥97% and chromaticity uniformity of ±0.003 Cx,Cy. Point-by-point correction is the core means to address this issue.

2. Accumulation of errors during manufacturing and use

During the production process, factors such as module assembly accuracy, mask flatness, and uneven heat dissipation can further amplify the differences in LEDs. For example, machining errors may lead to inconsistent spacing between light boards, resulting in bright or dark lines. Over long-term use, LEDs exhibit varying degrees of light decay, with brightness potentially decreasing by 3%-5% annually, and chromaticity gradually shifting. If not corrected, the screen will become visibly "blotchy" after 1-2 years of use, significantly reducing its commercial value.

3. Rigorous requirements for high-end applications

With the widespread adoption of LED displays in fields such as advertising, stage performances, and surveillance, users' demands for display quality are escalating. For instance, live broadcasts of large-scale concerts or sports events necessitate screens that maintain consistent color across various viewing angles, whereas surveillance centers require precise grayscale representation to prevent misinterpretation of information. Point-by-point calibration technology can enhance brightness uniformity to over 98% and control chromaticity non-uniformity within Δu'v'=0.0014, thereby fulfilling the requirements of these high-end scenarios. For instance, the LED screen provided by Lianchengfa for CCTV's live broadcast room of the Tokyo Olympics achieved seamless splicing and ultra-high-definition display through point-by-point calibration, ensuring a consistent visual experience for global viewers.

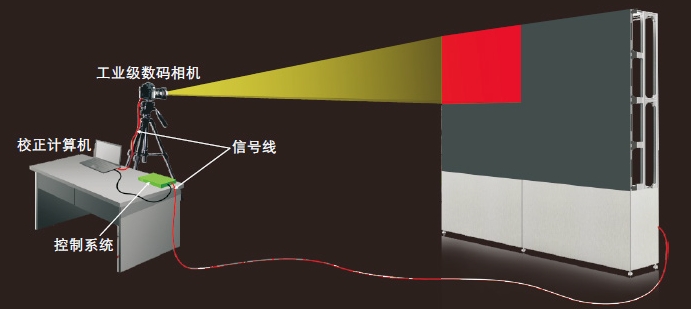

4. Technological advancements drive the popularization of correction

Early point-by-point calibration relied on manual operations, which were inefficient and costly. Nowadays, automated calibration systems based on CCD or CMOS sensors have become mainstream. For example, Dongguan Aarti's patented technology achieves real-time calibration in dynamic scenes through algorithm optimization, improving calibration efficiency by 20%. At the same time, the development of dynamic calibration technology has further addressed the aging issue - by monitoring the module lighting time in real-time, predicting the degree of light decay, and automatically compensating, it extends the screen life by more than 30%. These technological breakthroughs have enabled point-by-point calibration to move from high-end customization to large-scale application.

5. Economic Benefits and Sustainability

Point-by-point calibration not only enhances display quality but also significantly reduces maintenance costs. Taking a display screen worth millions as an example, regular calibration can extend the "eye-pleasing lifespan" from 15,000 hours to 30,000 hours, reducing the frequency of replacement. Furthermore, the calibrated screen has a higher residual value in the second-hand market, aligning with the concept of green environmental protection. The intelligent calibration instrument developed by Xiamen Quality Inspection Institute achieves precise compensation under different temperatures and viewing angles through adaptive algorithms. After calibration, the uniformity of white brightness reaches 98.5%, greatly enhancing the market competitiveness of the product.

Point-by-point correction is the key to transitioning LED displays from "usable" to "user-friendly". By addressing issues such as LED discreteness, manufacturing errors, and aging, it meets the stringent demands of high-end applications while yielding significant economic benefits. With continuous technological advancements, point-by-point correction will become a standard feature of LED displays, propelling the display industry towards higher quality development. Whether it's the vibrant colors of commercial advertising or the precision and reliability of industrial monitoring, point-by-point correction silently ensures the perfect presentation of every pixel behind the scenes.

Technology | Comparison between COB display and traditional SMD display

Technology | Modules vs. cabinets, which one is the best choice?

Mengling is a global provider of LED displays. We show premium technology with cutting-edge technology and advanced innovations, providing LED display products, solutions,and services worldwide for rental stage events, ads billboards, commercial display, etc.

Building 1, Zhongzhan Technology Park, No. 9 Furong Road, Tantou Community, Songgang Street, Shenzhen